ABOUT US

Anhui Daisy

Power Co.,Limited

Our History

-

Pool Cover Box (2012-2013)

Customer: Daisy Pool Covers and Rollers Austalia

In 2012, Daisy developed a new product to meet the need for a luxury pool cover box, which had an automatically opening lid and power roller. This unit had both a remote control, as well as push buttons, was solar powered and had the option for mains charging. Anhui Daisy Power developed the production system and manufactured this product, using custom actuators and tubular motors, in powder coated aluminium frames.

-

Pool Cover Roller System(2014)

Customer: Daisy Pool Cover Australia

This electric pool cover roller has a remote control as well as push buttons and has an optional solar panel for charging, so no wiring is required. The control box and drive are designed for volume production, using diecast aluminium to provide an IP66 housing. It is designed for bubble solar covers. Over 3,000 units are in operation in Australia, operating reliably under the harshest conditions. -

Drinking Fountain (2015)

Customer: Street Furniture Australia

The Drink Fountain was designed by Street Furniture Australia some decades ago, but they were having difficulty obtaining suppliers in China which could meet the tight tolerance and surface finish requirements. The fountain body was made of 3 pieces of aluminium, which had to be welded together, with polished seams and zero defects, so that it could be powder coated in Australia to customer order. We designed a custom stretch forming machine to manufacture the 2 dimensionally curved blade and custom jigs to control the body shape during welding, which was required to be carried out in climate controlled conditions, to ensure perfect weld seams and zero distortion. -

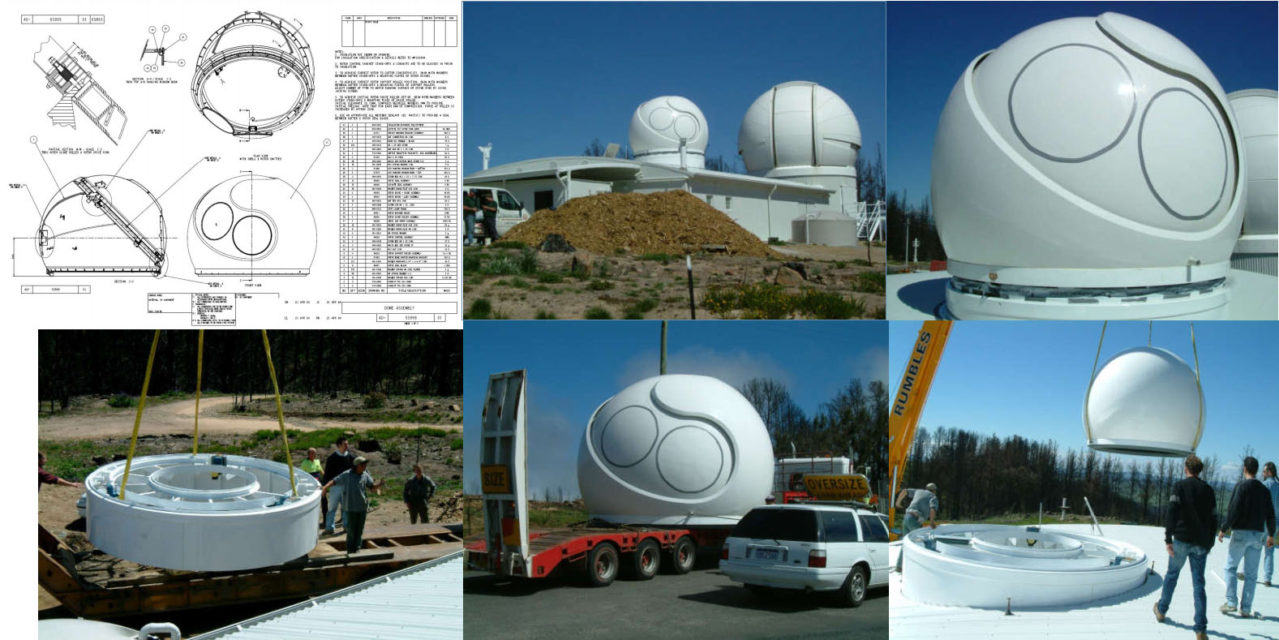

Typhoon Laser Dome(2016)

Customer: Electro Optic Space Systems, Australia

This 4.5m two-axis, insulated all-weather FRP dome is designed for unattended operations in harsh environments (to 200kph), allowing for full thermal control of the telescope inside. It has extreme positioning requirements (+/- 10mm absolute) and seals for pressurised, dustproof operation to cleanroom specifications. This requires extremely accurate 4m diameter slewing rings, which we formed from RHS and machined on a vertical lathe to 2mm concentricity. A total of 5 AC servo motors produce speeds to 10°/sec at 10°/sec2 acceleration. MTBF > 60,000 operational hours. -

IP68 Underwater Motors and Control Systems (2017-2018)

Customer: Various, from Russia, Belgium, France, Czechoslovakia, Switzerland and Spain

In 2017, we attended Aquanale in Cologne, Talking to many potential customers, we found that some customers had quality problems with their existing suppliers (e.g. from France) and that the IP68 motors from Belgium and Germany were extremely expensive. Several clients asked us whether we could develop a reliable IP68 pool cover motor that would sell at an attractive price. Using our 5 years experience in product development, we designed and prototyped a new design in 316 stainless steel, that we took to Piscine, Lyon in 2018 and which we have been testing ever since. We have now supplied these motors to customers in 6 countries and have commenced volume manufacturing. Although we a relatively new to this market, our customers are all very happy with our quality and level of service. -

Above Ground Post Cover Roller System (August 2019))

The above ground pool cover roller systems on the market have very poor aesthetics. They do not express current design trends. In response, in 2019, we designed and developed the latest generation of above ground roller drives. The attractive column has a cool LED lamp in the top lid, from which users can easily determine the battery level, by simply touching the lid.

-

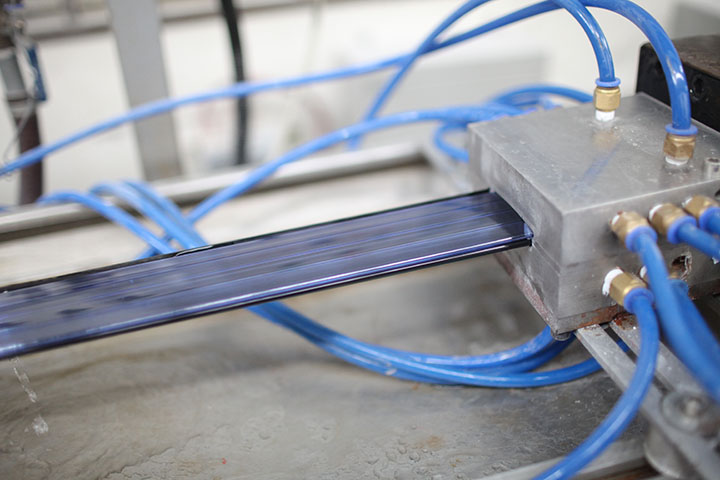

Polycarbonate slats pool cover (July 2019)

Customer: Various, from Russia, Belgium, France, Czechoslovakia, Switzerland and Spain

To ensure quality control, so that we could absolutely guarantee our slat performance, we developed our own molds, manufacturing and mass production system for PC slats. Our slats are made to European standards, in particular passing or exceeding the necessary UV resistance, chlorine resistance and impact resistance tests, proven in an independent Australian laboratory. Because the 6 month development was so successful and all standards were well demonstrated, we can now offer our customers a full set of SLAT COVER product lines, including, motors, controls, flanges, PC slat covers etc.